Ho netefatsa polokeho le boleng ba welding, mekhoa e latelang ea tlhahlobo le ho e lokisa e tlameha ho lateloa ka thata pele e qala le nakong ea ts'ebetso:

I. Litokisetso Pele ho Qala

1.Tiiso ea Khokahano ea Potoloho

Lekola likhokahano tsa phepelo ea motlakase ka hloko ho netefatsa likhoele tse nepahetseng, haholo terata ea fatše, e tlamehang ho sireletseha ho thibela likotsi tsa motlakase joalo ka ho lutla kapa li-circuits tse khutšoane.

Netefatsa hore lithapo tsohle tsa mats'oao le taolo li hoketsoe ka nepo ho qoba ho se sebetse hantle ha thepa ka lebaka la ho se kopane hantle.

2.Tlhahlobo ea Phepelo ea Khase

Likhase tse nang le bohloeki bo phahameng (mohlala, argon, helium) li khothaletsoa e le likhase tse sireletsang ho arola oksijene ka nepo le ho thibela oxidation ea weld.

Khase e tlameha ho hloka oli, e hloke mongobo, 'me e ome ho qoba litšila tse ka senyang botsitso ba letamo la weld le boleng ba seam sa weld.

II.Lisebelisoa tsa LaserTlhahlobo ea ho Qala

Pele o bula, etsa bonnete ba hore konopo ea ho emisa ha ts'ohanyetso ha e sebetse 'me lemati la tšireletso le koetsoe.

Ka mor'a ho bulela matla a maholo, hlahloba phanele ea taolo ho netefatsa hore ha ho na lialamo kapa matšoao a phoso a sebetsang.

III. Tlhahlobo ea Beam Path le ho tsamaisana ha Beam e khubelu

Ela hlokolebala le lefubeluboemo ba ho tsoa. Kenya ts'ebetso letšoao le khubelu 'me u hlahlobe hore na ho na le sepakapaka se hlakileng, se tsepamisitsoeng.

Ha e hlahisoa ho workpiece,sefate se sefubelu se lokela ho theha boholo ba chelete ea tšepe, letheba le hlakileng le senang matheba a lefifi, le bontshang tsela e sa thijoang le e hlwekileng ya maballo.

Haeba khanya e khubelu e bonahala e le lerootho, e hasane, kapa e hlahisa matheba a lefifi, hloekisa lilense hang-hang kapa u hlahlobe ho baloa ha maballo.

Tlhahlobo ea Boemo ba Beam e khubelu

Lebala le khubelu le tlameha ho lula le tsepamisitsoe holim'aterata e tjheseletsang ho etsa bonnete ba hore tsela ea welding e nepahetse. Haeba kheloha e etsahala, lokisa boemo ba hlooho ea lebone kapa laser bakeng sa ho lekanya.

Ho se tsamaisane hantle ho ka baka bofokoli ba ho chesella, ho se nepahale hantle ha manonyeletso, kapa esita le mefokolo ea sebopeho.

IV. Litlhokomeliso le Likhopotso tsa Tšireletseho

Ts'ebetso ea ho qala e tlameha ho etsoa ke basebetsi ba koetlisitsoeng feela.

Apara tse khethehilenglikhalase tsa tšireletso tsa lasernakong ea ts'ebetso ho sireletsa khahlanong le mahlaseli a laser a tobileng kapa a qhalakaneng.

Basebeletsi ba sa lumelloeng ba tlameha ho qoba hlooho ea laser le sebaka sa mosebetsi, haholo-holo nakong ea ho ntša laser.

Haeba ho hlaha lerata, mosi, kapa lialamo tse sa tloaelehang, emisa mosebetsi hang-hang, khaola motlakase 'me u ikopanye le tšehetso ea tekheniki.

V. Ground Clamp and Gas Purge Treatment

Hokela clamp ea fatše tafoleng ea welding kapa workpiece ho netefatsa potoloho e nepahetseng ea motlakase, ho thibela maikutlo a sa tloaelehang a hona joale a ka senyang thepa.

Hlakola switch ea fatše ka khase nako e khuts'oane. Ke hobane'ng ha mohato ona o hlokahala? Ho thibela ho bokellana ha lerōle kapa ho fafatsa ka har'a tube ea calibration ea nozzle, e ka silafatsang kapa ea chesa

lense e sireletsang.

VI. Netefatso ea Parameter le Tokiso

Netefatsa litlhophiso tse nepahetseng, ela hloko matla, maqhubu a oscillation, amplitude ea oscillation, le lebelo la phepelo ea terata.

Kenya sesebelisoa sa laser switch ha u ntse u roetse likhalase tsa tšireletso tsa laser.

Nakong ea ho cheselletsa, boloka sethunya sa laser se le 45 ° -60 ° angle.

Ke Hobane'ng ha U Khetha Angle ea 45–60°?

1. Tšireletso ea Khase e Ntlafetseng

Hangata welding ea laser e sebelisa khase e sireletsang (mohlala, argon) ho thibela ho qhibiliha ha letamo la oxidation.

Sekhahla se sekametseng se tiisa khase e ts'oanang haholoanyane, ho ntlafatsa ts'ireletso ea ts'ireletso.

2.Ho Thibela Tšenyo ea Ponahatso ea Laser

Bakeng sa lisebelisoa tse bonesang haholo (mohlala, aluminiamo, koporo), beam e otlolohileng ea 90° e eketsa kotsi ea laser reflection ho khutlela tsamaisong ea optical, e ka bang silafatsa kapa ea senya lilense.

Mokhoa oa angled o tsamaisa likhatiso, ho sireletsa laser optics.

3.Optimizes Ho Kena le Weld Quality

Ho beakanya beam angle hantle ho lokisa ntlha e shebaneng le thepa, ho khothaletsa ho kenella ka nepo le sebopeho sa weld ha ho ntse ho fokotsa likoli joalo ka porosity kapa fusion e sa fellang.

4.Maneuverability e ntlafalitsoeng le Ponahalo

Boemo bo otlolohileng ba 90° bo ka sitisa pono ea opareitara.

Mokhoa o nang le angled o fana ka ponahalo le taolo e betere, e thusa ho latella seam sa weld habonolo.

Ke Hobane'ng ha U Lokela ho Qoba Angle ea 90 °?

1.Kotsi e kholo ea ho bonahatsa laser.

2.Ponahalo e thibetsoeng le bothata ba ts'ebetso.

3.Monyetla o eketsehileng oa liphoso (mohlala, porosity, slag kenyelello).

Mochini oa tjheseletsa oa lasere hloka ho nepahala ho feteletseng le ho ela hloko lintlha. Mohato o mong le o mong oa ho itokisa o bohlokoa ho netefatsaboleng ba weld le lisebelisoapolokeho.

Ho Foster Laser, re tšehetsa molao-motheo oa "Boleng ba Pele, Lintlha ke Tsa Bohlokoa." Ha re fane feela ka ts'ebetso e phahamenglisebelisoa tsa laser tjheseletsaempa hape e fana ka maemo, a hlophisitsoeng

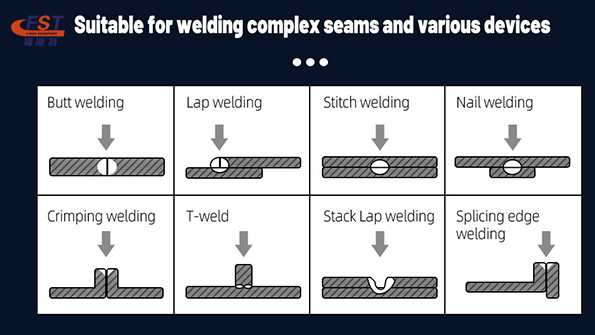

mekhoa ea ts'ebetso, ho matlafatsa li-welders ho sebetsana le mesebetsi e rarahaneng ka kholiseho.

Ho khetha Foster ho bolela ho fetang ho khetha mochine-ho bolela ho sebelisana le molekane ea tšepahalang le ea tsitsitseng. E se eka qalo e 'ngoe le e' ngoe e ka qala ka thata le ka nepo, 'me e se eka seam se seng le se seng sa weld se ka kenyelletsa

botsebi le tshepo.

Nako ea poso: Jun-27-2025