Ha tsoelo-pele ea indasteri e ntse e tsoela pele ka potlako,mechine ea ho itšeha ka laserba fumane ts'ebeliso e atileng. Leha ho le joalo, ka mor'a tšebeliso ea nako e telele, ho nepahala ha mechine ena ho ka 'na ha e-ba le ho kheloha ho itseng, ho fella ka lihlahisoa tse ka' nang tsa se ke tsa finyella litekanyetso tse lakatsehang. Liphapang tsena hangata li bakoa ke litaba tse nang le bolelele ba tsepamiso. Ka hona, ho bohlokoa ho utloisisa mokhoa oa ho lekanya ho nepahala ho itšeha ha mechini ea ho itšeha ea laser. Mona, re tla hlahloba mekhoa ea ho fetola ho nepahala ho itšeha ha mechine ea ho itšeha ea fiber laser.

Ha letheba la laser le fetotsoe ho boholo ba lona bo nyane, etsa tlhahlobo ea matheba ho fumana phello ea pele. Boemo ba ho tsepamisa maikutlo bo ka khethoa ka ho lekola boholo ba letheba la laser. Hang ha letheba la laser le fihla boholo ba lona bo tlase, boemo bona bo emela bolelele bo nepahetseng ba ts'ebetso, 'me u ka tsoela pele ka ts'ebetso ea machining.

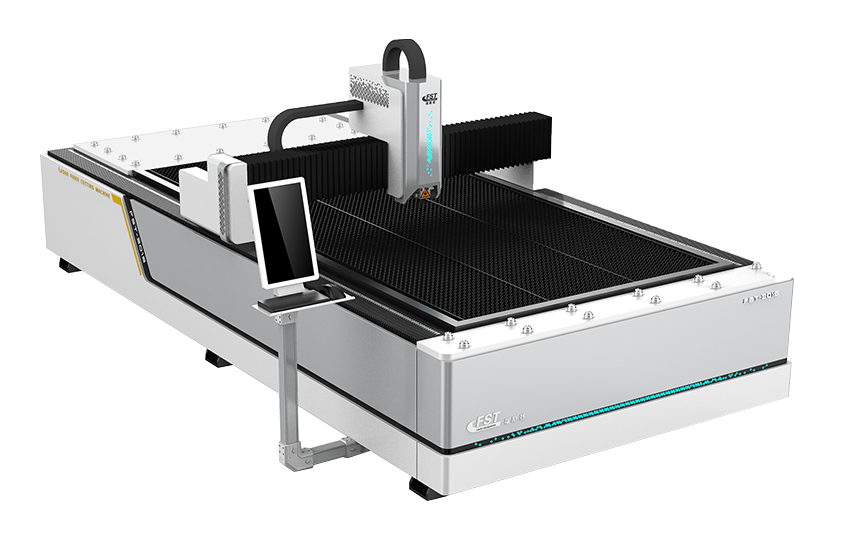

Mekhahlelong ea pele eamochini oa ho itšeha oa laserteka-tekano, o ka sebelisa pampiri e itseng ea teko kapa thepa e lahliloeng ho etsa liteko tsa letheba le ho fumana bonnete ba boemo bo tsepamisitsoeng maikutlo. Ka ho lokisa bolelele ba hlooho ea laser holimo le tlase, boholo ba letheba la laser bo tla fapana nakong ea liteko tsa letheba. Litokiso tse phetoang maemong a fapaneng li tla u thusa ho tseba sebaka se senyenyane sa laser, se u lumella ho tseba bolelele ba sebaka se nepahetseng le boemo bo nepahetseng bakeng sa hlooho ea laser.

Ka mor'a ho kenngoa hamochini oa ho itšeha oa laser fiber, sesebelisoa sa scribing se kenngoa molomong oa mochine oa ho itšeha oa CNC. Sesebelisoa sena se sebelisetsoa ho ngola mokhoa o ts'oanang oa ho itšeha, e leng lisekoere-mithara tse 1 tse nang le selikalikoe sa bophara ba limithara tse 1 se ngotsoeng ka hare ho sona. Methalo ya diagonal e ngotsoe ho tloha lihukung tsa lisekoere. Hang ha ho ngola ho phethiloe, lisebelisoa tsa ho metha li sebelisoa ho netefatsa hore na selikalikoe se tangent ho ea mahlakoreng a mane a lisekoere. Bolelele ba li-diagonals tsa lisekoere e lokela ho ba limithara tse √2, 'me motsoako o bohareng oa selikalikoe o arole mahlakoreng a sekoere. Lintlheng tseo axis e bohareng e kopanang le mahlakoreng a sekwere e lokela ho ba limithara tse 0.5 ho tloha likhutlong tsa lisekoere. Ka ho lekanya sebaka se pakeng tsa li-diagonal le lintlha tsa mateano, ho nepahala ha lisebelisoa ho ka khethoa.

Nako ea poso: Aug-20-2024