Ka lilemo tse ngata, Foster e ntse e inehetse ho etsa lipatlisiso, nts'etsopele le tlhahiso ea mahlale a mantlha a lisebelisoa tsa laser, ho theha boteng ba bohlokoa lebaleng la welding ea laser. Khampani e hlahisa lisebelisoa tse fapaneng tsa ho tjheseletsa, ho kenyeletswa metjhini e tjheseletsang laser e tshwarang ka letsoho, metjhini e tjheseletsang moya, le metjhini e tjheseletsang laser ya roboto.

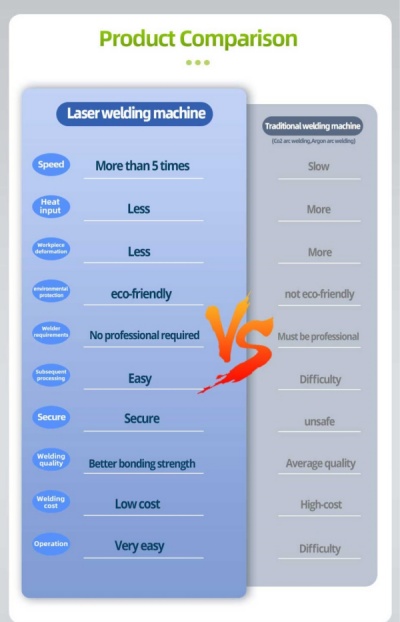

Laser welding, e sebelisang laser e le mohloli oa mocheso, e tšoauoa ka ho kenella ka botebo, ho nepahala ho phahameng, lebelo la ho tjheseletsa ka potlako, sebopeho se setle, le ho kenya mocheso o tlase. E tsejoa ka ho pharaletseng e le e 'ngoe ea mahlale a sebetsang hantle ka ho fetisisa a ho cheselletsa, e khonang ho fihlela litlhoko tsa ho tjheseletsa le ho etsa thepa ea likarolo tse rarahaneng tsa sebopeho.

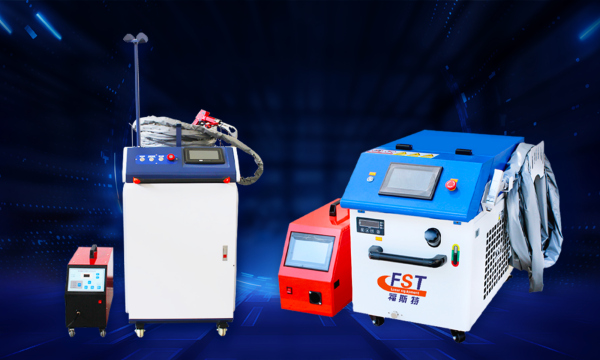

mochini o futhumatsang oa laser oa metsi o pholileng

Mochini oa welding oa Fiber laser o loketse tšepe e sa hloekang, koporo, aluminium, khauta, chromium, silevera, nickel le litšepe tse ling kapa lialloys. E ka boela ea sebelisoa bakeng sa mefuta e sa tšoaneng ea ho cheselletsa pakeng tsa lisebelisoa tse fapaneng, tse kang koporo ea koporo, nickel - koporo joalo-joalo. Kopana le litlhoko tsa ho cheselletsa likhabote tsa kichineng, lifti tsa litepisi, lishelefo, lionto, mamati a tšepe le lifensetere tse sireletsang, limpho tsa mesebetsi ea matsoho, thepa ea lapeng le liindasteri tse ling.

1, 4IN 1 e nang le litšenyehelo tse phahameng haholo e ka tjheseletsa, e hloekisa le ho seha lisebelisoa tsa tšepe;

2, Ho fihla ho 3kw laser

3, 0.7kg e nyenyane ka ho fetisisa tjheseletsa toche.

4, Lebelo la ho tjheseletsa ka lebelo (welding 7.2 metres ka motsotso o le mong)

5、 Sehokelo sa sesebelisoa sa ho fepa ka terata

moea o pholileng ka laser tjheseletsa mochini

Mochine ona o amohela laser ea fiber ho etsa welding / ho itšeha / ho hloekisa ka hlooho ea ho tjheseletsa tse 'nè. Sistimi e ka etsa phetoho ka bolokolohi ho latela maemo a fapaneng a ts'ebeliso, e fana ka tharollo e fapaneng bakeng sa litlhoko tse fapaneng tsa ts'ebeliso ea basebelisi. E loketse setsi sa welding, ho hloekisa ho hlokahalang le ho itšeha habonolo

1.Ha ho Pholiso ea Metsi e Hlokehang: E sebelisa mokhoa oa ho futhumatsa moea ho e-na le mokhoa o tloaelehileng oa ho futhumatsa metsi, ho fokotsa ho rarahana ha lisebelisoa le ho itšetleha ka mehloli ea metsi.

2.Bonolo ba Tlhokomelo: Lisebelisoa tsa ho pholisa moea li bonolo ho li boloka ho feta mekhoa ea ho pholisa metsi, ho fokotsa litšenyehelo tsa nako e telele tsa ts'ebetso le boiteko bo ka sehloohong.

3.Tlhahiso e Matla ea Tikoloho: Ho ba sieo ha tlhokahalo ea ho pholisa metsi ho nolofalletsa mechine ea laser e pholileng ea moea hore e sebetse libakeng tse ngata tse fapaneng, haholo-holo libakeng tseo metsi a haellang kapa boleng ba metsi bo amehileng.

4.Portability: Mechini e mengata ea laser e pholileng moeeng e etselitsoe hore e tšoaroe ka letsoho kapa e nkehe, e etsa hore e be bonolo ho tsamaea le ho e sebelisa ho pholletsa le maemo a fapaneng a mosebetsi.

Welding ea Roboto ea Six Axis Arm

Foster Laser Welding Robot ke sesebediswa se ikgethang sa laser welding se nang le hlooho ya tjheseletsa ya laser ya indasteri le Six Axis Robot Arm. E fana ka ho nepahala ha boemo bo phahameng le mefuta e mengata ea ts'ebetso. Khokahano ea li-axis tse tšeletseng e thusa ho cheseletsa ka mahlakore a mararo, ho loanela ho boloka litšenyehelo. Roboto ena e kopana le litlhoko tsa bareki bakeng sa welding e feto-fetohang ea lishiti le likaroloana. E lumellana haholo le libopeho tsa likarolo tse cheselitsoeng 'me e fana ka phetoho e hlokahalang bakeng sa li-workpieces tse rarahaneng

Foster Laser Welding Machines e hlahisitse mefuta e mengata ea mekhoa le lisebelisoa tsa ho tjheseletsa, Foster drives line automation le mekhoa e bohlale ea feme e nang le welding laser, e thusang likhoebo tse ngata ho potlakisa tsoelo-pele ea tsona.

Nako ea poso: Jun-15-2024