Foster Laser Handheld Welding Machine, e fanang ka boiphihlelo ba batho ba bane ho e le 'ngoe, e ntlafalitsoe hape! Sena se bane-in-one multifunctionalmochini oa welding oa laser o pholileng ka moeae na le boholo bo fokolang le ts'ebetso e matla haholoanyane. Liphetoho tse ngata tsa theknoloji li eketsa bokhoni ba eona ba ho kopana le lits'ebetso tse fapaneng tsa welding.

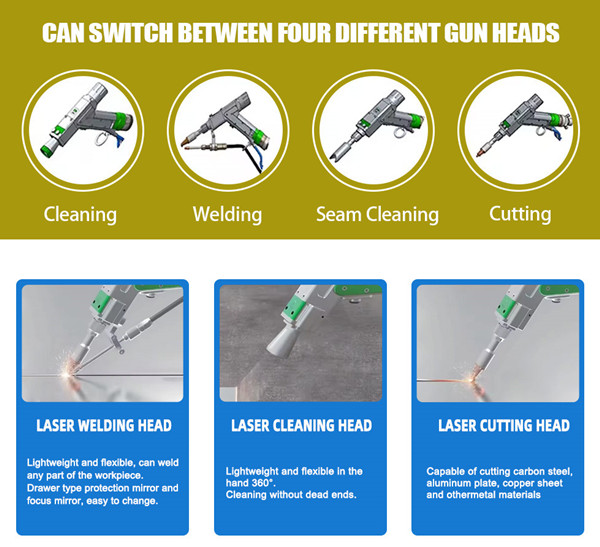

Mochine ona o amohela laser ea fiber ho etsa welding / ho itšeha / ho hloekisa ka lihlooho tse 'nè ho tse' ngoe. E loketse setsi sa welding, ho hloekisa ho hlokahalang le ho itšeha habonolo

Mona ke tse ling tsa tse robeli Melemo ea morao-rao ea phodiso ya moyaLasertjheseletsaMochini:

1,Ha ho Pholiso ea Metsi e Hlokehang: E Sebelisaphodiso ya moya tsamaiso ho e-na le mokhoa o tloaelehileng oa ho futhumatsa metsi, ho fokotsa ho rarahana ha lisebelisoa le ho itšetleha ka mehloli ea metsi.

2,Boiketlo ba Tlhokomelo: Lisebelisoa tsa ho pholisa moea li bonolo ho li boloka ho feta mekhoa ea ho pholisa metsi, ho fokotsa litšenyehelo tsa nako e telele tsa ts'ebetso le boiteko ba tlhokomelo.

3,Ho Ikamahanya le Boemo bo Matla ba Tikoloho: Ho ba sieo ha tlhokahalo ea ho pholisa metsi ho nolofalletsa mechini ea welding ea laser e pholileng moeeng hore e sebetse libakeng tse ngata tse fapaneng, haholo-holo libakeng tseo metsi a haellang kapa boleng ba metsi bo amehileng.

4,Portability: Mechini e mengata ea laser e pholileng ka moea e etselitsoe hore e tšoaroe ka letsoho kapa e nkehe, e etsa hore e be bonolo ho e tsamaisa le ho e sebelisa libakeng tse fapaneng tsa mosebetsi.

5,Ts'ebetso e Phahameng ea Matla: Mechini ena hangata e ithorisa ka ts'ebetso e phahameng ea ho fetola matla, ho bolelang hore motlakase o sebelisoa ka nepo nakong ea ts'ebetso ea ho cheselletsa.

6,Ts'ebetso e Batlang Basebelisi: E na le lihokelo tse bonolo tsa basebelisi, joalo ka liphanele tsa taolo ea sekirini sa touchscreen, tse etsang hore ts'ebetso ea mechini e otlolohe ka pele le ka mokhoa o hlakileng.

7,Ho sebetsa ka mefuta-futa: E khona ho tjheseletsa mefuta e mengata e fapaneng ea thepa le botenya, ho kenyeletsoa empa e sa felle feela ka tšepe e sa jeleng, tšepe ea k'habone le lialloi tsa aluminium.

8,Li-Welds tsa boleng bo holimo: E fana ka liphetho tse nepahetseng le tse phahameng tsa welding tse nang le li-welds tse boreleli le tse khahlehang, libaka tse anngoeng ke mocheso o fokolang, le khopamo e tlase.

Ba 4 ho 1laser welding ho hloekisa mochine oa ho itšehae ke ke ea hloekisa litšila holim'a tšepe feela, empa hape le weld le ho khaola lisebelisoa tse fapaneng tsa tšepe. Ke sesebelisoa sa laser se sebetsang ka bongata, 'me se na le mekhoa e meraro ea ho hloekisa le ho itšeha, e ka fetoloang habonolo.

Lisebelisoa tsa kopo: Stainless Steel, Carbon Steel, Aluminium le Aluminium Alloys, Copper le Copper Alloy Titanium Alloys, joalo-joalo.

Sebaka sa Kopo: Ho Etsa Likoloi, Aerospace, Electronics le Microelectronics Medical Devices, Indasteri ea Mabenyane, Lekala la Matla, Tlhahiso ea Mechini, Liphaephe le Boenjiniere ba Stuctural.

Ka kopo ikutloe u lokolohile ho ikopanya le rona haeba u na le litlhoko leha e le life!

Nako ea poso: May-18-2024